Project Overview

- Industry: Consumer Electronics / Smartphone Manufacturing

- Application: Non-contact 3D inspection of curved glass panels

- Technology Used: SHINING 3D OptimScan 5M Plus

- Objective: Improve inspection accuracy, efficiency, and repeatability for curved glass components

Challenge: Inspecting Delicate Smartphone Curved Glass Panels

Curved glass panels are an essential component in modern smartphone design, offering enhanced ergonomics, aesthetic appeal, and immersive visual performance. However, the inspection of these precision parts introduces several challenges:

- Deformation Sensitivity:

Hot pressing introduces natural curvature deviations; any contact during inspection risks distorting these delicate components. - Dimensional Complexity:

Curved edges, compound angles, and tight tolerances complicate manual or contact-based measurement. - Inaccurate Traditional Tools:

Calipers and coordinate-measuring machines (CMMs) fail to deliver the precision or speed needed for mass production lines.

Pain Point: Manual inspection tools are inefficient, inconsistent, and risk damaging the very components they’re meant to evaluate.

Solution: OptimScan 5M Plus for High-Accuracy, Non-Contact 3D Inspection

To address these issues, SHINING 3D introduced the OptimScan 5M Plus, a desktop 3D scanning system designed for ultra-precise, non-contact inspection of high-value small components like smartphone glass panels.

Key Features & Technical Advantages

High-Resolution 3D Scanning

- Utilizes dual 5MP industrial-grade cameras

- Optical accuracy up to 0.005 mm

- Full scan completed in <1 minute using an automatic rotary table

Non-Contact Measurement

- Completely eliminates deformation risks associated with mechanical contact

- Ideal for thin, brittle, or pressure-sensitive surfaces

Rapid Throughput

- ≤1.5 seconds per single frame scan

- Fully automated scanning workflow enhances factory productivity

Complete Data Acquisition

- Captures fine curvature and edge transitions with high repeatability

- Supports full 3D mesh export for post-analysis and digital records

Advanced 3D Inspection with Auto Reporting

Once scanning is complete, the data is imported into compatible 3D inspection software for automated analysis and reporting.

Inspection Highlights:

- 10-minute initial path programming

- 1-minute auto-report generation

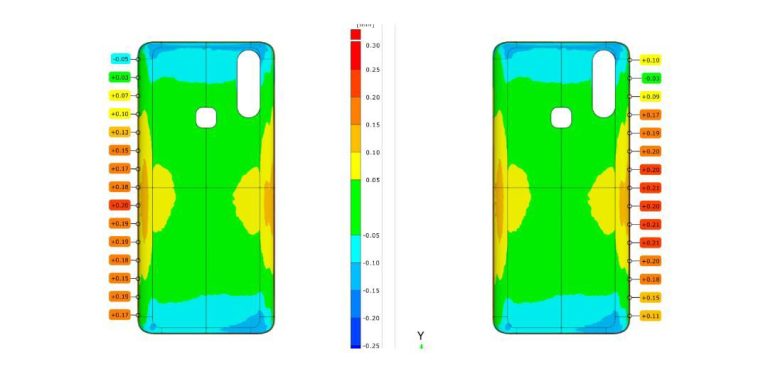

- Detailed visualizations of:

- Curvature variations on all four sides

- R-angle (corner radius) analysis

- Cross-sectional deformation trends

- Appearance contour deviations

- Full surface deviation maps (chromatograms)

These reports enable real-time process corrections, quality audits, and statistical process control—improving yield rates and reducing costly rework.

Results: Enhanced Inspection Accuracy & Production Efficiency

| Metric | Before (CMM/Calipers) | After (OptimScan 5M Plus) |

|---|---|---|

| Inspection Time per Panel | ~10–15 minutes | <1 minute |

| Risk of Deformation | High | Eliminated |

| Report Generation | Manual, Slow | Automated, Instantaneous |

| Accuracy & Repeatability | Inconsistent | ±0.005 mm |

Conclusion: A Scalable Metrology Upgrade for Smart Device Production

The OptimScan 5M Plus enables smartphone manufacturers to meet the rising demand for tighter tolerances, faster inspections, and smarter quality control. By replacing contact-based tools with non-contact optical metrology, manufacturers can unlock higher yields, fewer defects, and greater customer satisfaction.